Aagaard A/S is a leading manufacturer of a large range of Unique Air Filtration Systems since 1965. Efficiency using modern technology and manufacturing equipment.

Our goal is always to put ourselves at the cutting edge of technology and development in dust control and process filtration.

Our goal is always to put ourselves at the cutting edge of technology and development in dust control and process filtration.

Combining Danish manufacturing with British engineering to provide customers from a large range of markets the most effective solutions.

With the UK office based in the heart of the Midlands, we offer services from; small modifications, LEV testing, component only to full turnkey solutions throughout the whole of the UK & Ireland.

We can provide bespoke solutions for all your dust containment requirements. Dust and fume extraction are a main requirement of most manufacturing industries. Our dust extraction units can remove particles from the workplace for a wide range of materials such as wood, metal, chemicals and composites.

Our bespoke units range from stand-alone dust extraction systems for one machine, to larger, centralised dust control systems.

T 01746 557117

sales@aagaard.co.uk

www.aagaard-systems.co.uk

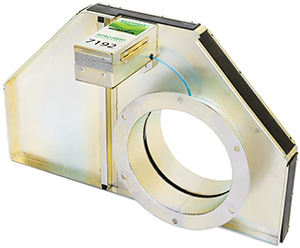

Aagaard UK in 2022 became official distributors for ECOGATE system

First introduced over here back in 2010, Ecogate technology has had a major impact on the UK woodworking industry, with a multitude of joinery and furniture manufacturing companies now benefiting significantly from the huge reductions in power consumption the system can deliver – typically returning savings of between 50% and 75% on dust extraction costs with an average return on investment period of just 2 years for the majority of installations.

Aagaard UK sales Director, Elliot Webb stated, “Our aim is to ensure our customers’ extraction systems are operating to their full potential, at lowest cost; allowing factory owners to concentrate on the business of manufacturing, with Energy prices becoming a major issue, it’s more important than ever to get control of your power usage.”

Ecogate® technology installed on a dust-producing production line is that the system is custom-programmed to extract only when individual machines are running, and to extract only the minimum volumes required to transfer dust-laden air from each machine to the filter unit for collection.

Potential financial gains are ruled by the laws of physics, but just a 20% reduction in fan speed will reduce power consumption by 50% and in many factories, where it’s estimated that less than half of the machines are in use at any one time, even bigger savings can be achieved. Aagaard UK offer a free site-survey to ascertain the possible savings that Ecogate® technology could make but, as a general rule, electricity costs will be at least halved and, whether you have just one machine or a whole factory-full – the Ecogate® greenBOX MASTER SRL® can control up to four extraction fans and as many as 180 workstations – the same principles apply. These can be easily retrofitted.

The fully-automated, intelligent system provides accurate analytical data to keep operators fully informed of the system’s efficiency, and the lower energy consumption will also contribute to a reduction in a company’s carbon footprint. In addition, the ‘spare’ extraction capacity made available by reducing the fan speed gives business owners a margin for production line expansions without the need to invest in more powerful fans and larger filters.

If you would like more information on how Ecogate® technology could significantly reduce your energy bills, please call: 01746 557117 or email: sales@aagaard.co.uk.