POLIGRAT has been duly selected as our reputable Surface Finish Specialist of the Month, we are pleased to announce here at Building and Facilities News, the publication focused on promoting businesses of great value within the construction and facilities management sectors.

With roots dating back to 1952 (when the company was officially established by Mr. Erich Stoeckl), POLIGRAT is a long established surface technology provider with decades of refined industry experience. Continued success has enabled the enterprise to grow significantly, acquiring a nationwide presence with its headquarters in Munich and additional sites in Germany, France, Hungary and the UK.

With roots dating back to 1952 (when the company was officially established by Mr. Erich Stoeckl), POLIGRAT is a long established surface technology provider with decades of refined industry experience. Continued success has enabled the enterprise to grow significantly, acquiring a nationwide presence with its headquarters in Munich and additional sites in Germany, France, Hungary and the UK.

The organisation focuses on the development of processes and products for the treatment of different metal surfaces; namely materials such as aluminium, stainless steel, cobalt alloys, carbon steel, copper, copper alloys, magnesium, nickel, nickel alloys, rare metals, titanium, zinc and zirconium.

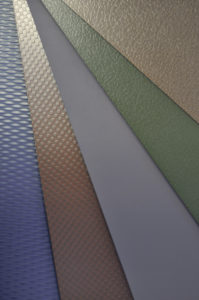

“Our processes produce smooth and attractive long lasting finishes and colours (gloss or matt),” detailed Siegfried Pießlinger-Schweiger, Managing Director at POLIGRAT. “In addition they are easy to clean, anti-fingerprint, high corrosion resistant, UV-resistant, food safe, repeatable and not combustible, so they come with a whole host of benefits.

“We don’t have much competition in most of our markets; therefore we hold a preferential position as one of the foremost international leaders in technology for this particular industry (surface treatment). In general we have customers in all areas with high demand for surface quality and performance – and it is within this field that we can provide added value for various organisations.”

“We don’t have much competition in most of our markets; therefore we hold a preferential position as one of the foremost international leaders in technology for this particular industry (surface treatment). In general we have customers in all areas with high demand for surface quality and performance – and it is within this field that we can provide added value for various organisations.”

Offering finishes for decorative, functional and burr-free surfaces, POLIGRAT’s practices involve electro-polishing, chemical polishing, deburring, pickling and passivating. It’s most recent treatment method, however, revolves around the utilisation of sol-gel coatings (glass) which are transparent and colour protective on stainless steel, aluminium and zinc.

Offering finishes for decorative, functional and burr-free surfaces, POLIGRAT’s practices involve electro-polishing, chemical polishing, deburring, pickling and passivating. It’s most recent treatment method, however, revolves around the utilisation of sol-gel coatings (glass) which are transparent and colour protective on stainless steel, aluminium and zinc.

These relatively new products, named POLISEAL and VEROPRECTRAL, have already made a positive impression on customers, as Siegfried told us, “We have found there is a very high interest for these specially developed sol-gel coatings. Their superior properties ensure they have a central place in architecture (outside and interior), although they are also predominantly asked for in sanitary & kitchen equipment, furniture, cabinets of machinery and the automotive sector.”

POLISEAL and VEROSPECTRAL – readily available for purchase this month – were stringently made at the company’s technical application centre as a contemporary way to improve upon surface metal handling. July marks the launch of these particular innovati

ons, as the new production line for Frankfurt will begin at this time, with the offering reaching maximum sizes of 6.0 x 2.0 metre sheets and panels.

POLIGRAT also offers cleaning, de-rouging, colouring/anodising and coating services, whilst the business itself operates via the following designated divisions: engineering & development, installation (plants & equipment), chemicals and subcontract work.

If you would like any more information about these tried and trusted services and products then please don’t hesitate to contact the team today – a friendly representative will be more than happy to discuss how these solutions can improve profitability, safety and productivity at your workplace.

T +44 (0)1252 336337

sales@poligratuk.co.uk

www.poligratuk.co.uk